产品介绍

产品结构特点 Construction features

1) 流体阻力小 闸阀阀体内部介质通道是直通的,介质流经闸阀时不改变其流动方 向,因而流动阻力较小;

2) 启闭较省力 启闭时闸板运动方向与介质流动方向相垂直,闸阀的启闭较为省力;

3) 介质流动方向一般不受限制介质可以从闸阀两侧任意方向流过,均能达到接通或 截断的目的,便于安装,适用于介质的流动方向可能改变的管路中;

4) 密封面磨损小 闸阀的阀体上设有导向机构,可防止闸板在开启或关闭时旋转, 从而保证密封面相应对准,并使闸板在未达到关闭位置之前不与阀座摩擦,从而减 少密封面的磨损;

5) 结构简单 闸阀的形状结构比较简单,制造工艺性较好,结构长度比较短。

6) 填料室设有真空密封结构,具有自胀压紧作用,并且密封采用高强膨胀材料密封,使系统与大气完全隔离,具有很好的系统气密封性。

1) The internal medium channel of the fluid resistance small gate valve body is straight through, and the flow direction is not changed when the medium flows through the gate valve, thus the flow resistance is smaller.

2) The movement direction of the gate is perpendicular to the flow direction of the medium when the opening and closing are more efficient than the other, and the gate valve's opening and closing are more efficient;

3) Medium flow direction is generally not restricted medium can flow from the gate on both sides of any direction, it can achieve the purpose of connected or truncate,easy to install, suitable for medium may change the direction of current flow in pipeline;

4) Sealing surface wear small gate valve body is equipped with guide mechanism,can prevent the disc rotate in open or closed, to ensure that corresponding alignment on sealing surface, and make the disc in the closed position has not been achieved before no friction with the valve seat, thereby reducing the wear of sealing surface;

5) The structure of simple gate valve is relatively simple, the manufacturing process is better and the structure length is shorter.

6) The packing chamber is equipped with vacuum seal structure, which has self-expanding pressure and compaction, and sealing with high pressure expansion material, so that the system is completely isolated from the atmosphere, and has a good system gas seal.

产品特征 Spericfications

适用介质:水、气、油品、天然气和酸碱腐蚀性介质

适用温度:-196~425℃

驱动方式:手动、气动、电动等

公称压力:1.0~4.0MPa

公称通径:DN50~1200mm

Applicable media: water, gas, oil, gas and acid and alkali corrosive medium

Applicable temperature: -196~425℃

Driver: manual, pneumatic, electric, etc

Nominal pressure: 1.0~4.0MPa

Nominal size: DN50~1200mm

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12234 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T9113 HG20592 |

| 试验和检验 Test & inspection | GB/T 26480 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | |||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

反密封试验 Sealing test |

气密封试验 Air seal test |

| 1.0 | 1.5 | 1.1 | 1.1 | 0.6 |

| 1.6 | 2.4 | 1.76 | 1.76 | 0.6 |

| 2.5 | 3.75 | 2.75 | 2.75 | 0.6 |

| 4.0 | 6.0 | 4.4 | 4.4 | 0.6 |

| 6.3 | 9.45 | 6.93 | 6.93 | 0.6 |

| 10.0 | 15.0 | 11.0 | 11.0 | 0.6 |

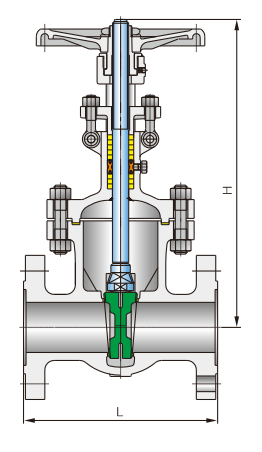

闸阀结构长度和外接尺寸 Main connection dimensions

| PN:1.0 | PN:1.6~2.5 | PN:4.0~10.0 | |||||||

|

公称通径 DN |

L (mm) |

H (mm) |

D0 (mm) |

L (mm) |

H (mm) |

D0 (mm) |

L (mm) |

H (mm) |

D0 (mm) |

| 50 | 180 | 345 | 200 | 250 | 350 | 220 | 250 | 360 | 250 |

| 65 | 195 | 360 | 220 | 265 | 370 | 240 | 280 | 385 | 300 |

| 80 | 210 | 380 | 240 | 280 | 390 | 280 | 310 | 420 | 300 |

| 100 | 230 | 430 | 280 | 300 | 435 | 300 | 350 | 450 | 350 |

| 125 | 255 | 520 | 300 | 325 | 520 | 320 | 400 | 540 | 400 |

| 150 | 280 | 520 | 300 | 350 | 610 | 350 | 450 | 630 |

|

| 200 | 330 | 765 | 400 | 400 | 787 | 400 | 550 | 820 |

|

| 250 | 380 | 930 | 450 | 450 | 930 | 450 | 650 | 960 |

|

| 300 | 420 | 1080 | 500 | 500 | 1080 | 500 | 750 | 1130 |

|

| 350 | 450 | 1200 | 500 | 550 | 1250 | 550 | 850 | 1300 |

|

| 400 | 480 | 1400 | 550 | 600 | 1430 | 600 | 950 | 1450 |

|

| 450 | 510 | 1500 | 600 | 650 | 1520 | 650 | 1050 | 1500 |

|

| 500 | 540 | 1630 | 650 | 700 | 1650 | 700 | 1150 | 1680 |

|

| 600 | 600 | 1830 | 700 | 800 | 1850 | 750 | 1350 | 1900 |

|

| 700 | 660 | 1930 | 750 | 900 | 1950 | 800 | 1450 | 2050 |

|

| 800 | 720 | 2170 | 800 | 1000 | 050 | 850 | 1650 | 2170 |

|

| 900 | 780 | 2300 | 850 | 1100 | 2150 | 900 |

|

|

|

| 1000 | 840 | 2600 |

|

1200 | 2250 | 950 |

|

|

|

| 1200 | 960 | 2900 |

|

|

|

|

|

|

|