产品介绍

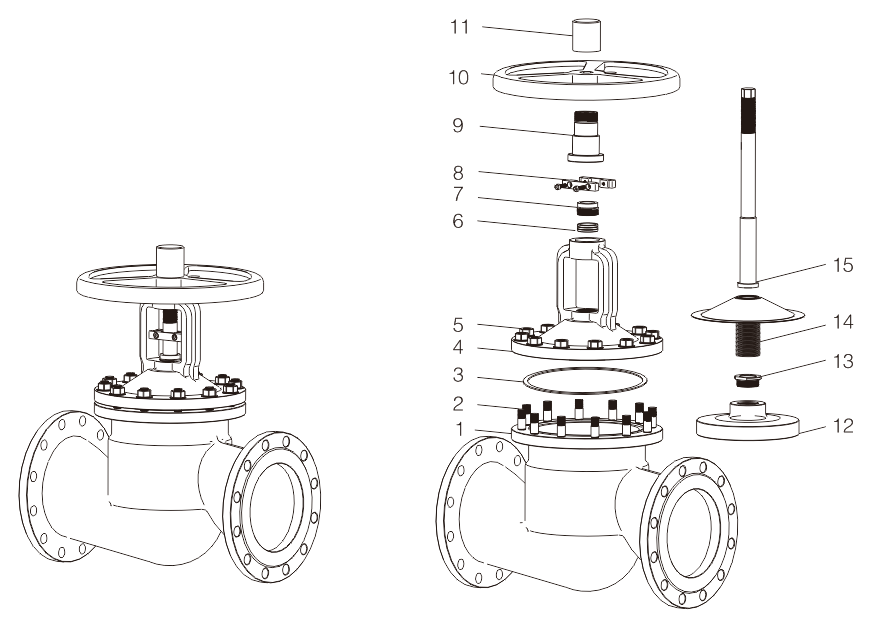

主要零件和材质 Main parts and materials

|

序号 NO |

零件名称 Accessor name |

材质 Material |

| GB系列 | ||

| 1 | 阀体 Body | WCB, LCB, WC6, WC9, CF8, CF3, CF8M, CF3M |

| 2 | 螺柱 Bonnet bolt | 35#, 304, 316 |

| 3 | 中垫 Gasket | 不锈钢+石墨 PTFE |

| 4 | 阀盖 Bonnet | WCB, LCB, WC6, WC9, CF8, CF3, CF8M, CF3M |

| 5 | 螺母 Nut | 45#, 304, 316 |

| 6 | 填料 Packing | 石墨 PTFE |

| 7 | 并帽 Lock nut | 45#, 304, 316 |

| 8 | 夹排 Clip line | Q235 |

| 9 | 阀杆螺母 Stem nut | ZGuAl10Fe3 |

| 10 | 手轮 Handwheel | 玛钢 QT450-10 |

| 11 | 手轮压帽 Bonnet cap | A105, F304, F316, F316L |

| 12 | 阀瓣 Wedge | A105, F304, F316, F316L |

| 13 | 阀瓣并帽 Bonnet cap | A105, F304, F316, F316L |

| 14 | 波纹管组件 Bellow assemble | F304, F316, F316L |

| 15 | 阀杆 Stem | 20Cr13, 304, 304L, 316, 316L, 38CrMoAL, 25Cr2MoV |

| 16 | 内六角螺钉 Nut | 35#, 304, 316 |

产品结构特点 Construction features

1.双重的密封设计(波纹管+填料)若波纹管失效,阀杆填料也会避免。

2.结构合理、密封可靠、性能优良、造型美观。

3.没有流体损失,降低能源损失,提高工厂设备安全。

4.密封面堆焊Co基硬质合金、耐磨、耐腐、抗摩擦性能好、使用寿命长,减少维修次数,降低经营成本。

5.坚固耐用的波纹管密封设计,保证阀杆的零泄漏,提供无需维护的条件。

6.截止阀阀杆调质及表面氮化处理,有良好的抗腐和抗摩擦性能;

7.阀杆升降位置指示更直观。

1. Double seal design (bellows + filler) if bellows fail, stem packing will be avoided.

2. Reasonable structure, reliable sealing, excellent performance and beautiful appearance.

3. There is no fluid loss, reduce energy loss, and improve the safety of plant equipment.

4. The cover surfacing the Co base carbide, wear-resisting, anti-corrosion, anti-friction performance, the service life long, reduce the maintenance times, reduce the operating cost.

5. Strong and durable bellows seal design to ensure zero leakage of stem and provide conditions without maintenance.

6. The cut-off valve stem and surface nitride treatment have good anti-corrosion and anti-friction properties;

7. Valve stem elevation position indication is more intuitive.

产品特征 Spericfications

适用介质:废水、热水、天然气、冷冻系列、蒸汽系列等

适用温度:-196~150℃

驱动方式:手动等

公称压力:1.0~4.0MPa

公称通径:DN15~350mm

Applicable media:

Wastewater, hot water, natural gas, frozen series, steam series, etc

Applicable temperature: -196~150℃

Driver: Manual etc.

Nominal pressure: 1.0~4.0MPa

Nominal size: DN15~350mm

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12235 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T9113 HG20592 |

| 试验和检验 Test & inspection | GB/T 26480 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | |||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

反密封试验 Sealing test |

气密封试验 Air seal test |

| 1.0 | 1.5 | 1.1 | 1.1 | 0.6 |

| 1.6 | 2.4 | 1.76 | 1.76 | 0.6 |

| 2.5 | 3.75 | 2.75 | 2.75 | 0.6 |

| 4.0 | 6.0 | 4.4 | 4.4 | 0.6 |

截止阀结构长度和外接尺寸 Main connection dimensions

| PN:1.6~4.0 | |||

|

公称通径 DN |

L (mm) |

H (mm) |

D0 (mm) |

| 15 | 130 | 120 | 100 |

| 20 | 150 | 140 | 120 |

| 25 | 160 | 140 | 140 |

| 32 | 180 | 160 | 160 |

| 40 | 200 | 160 | 200 |

| 50 | 230 | 180 | 220 |

| 65 | 290 | 200 | 240 |

| 80 | 310 | 220 | 280 |

| 100 | 350 | 250 | 320 |

| 125 | 400 | 300 | 350 |

| 150 | 480 | 350 | 400 |

| 200 | 600 | 400 | 450 |

| 250 | 730 | 450 | 550 |

| 300 | 850 | 500 | 650 |

| 350 | 980 | 550 | 750 |