Product Introduction

产品结构特点 Construction features

重量轻:本体采用高级球黑铸铁制成,重量较传统闸阀重量减轻约20%~30%,安装维修方便。

平底式闸座:传统的闸阀往往在通水洗管后即因外物诸如石头,木块、水泥、铁屑、杂物等淤积于阀底凹槽内,容易造成无法关闭紧密而形成漏水现象,弹性座封闸阀底部采用与水管机同的平底设计,不易造成杂物淤积,使流体畅通无阻。

整体包胶:闸板采用高品质的橡胶进行整体内、外包胶,欧洲一流的橡胶硫化技术使得硫化后的闸板能够保证精确的几何尺寸,且橡胶与球墨铸闸板接着牢靠,不易脱落及弹性记忆佳。

精铸阀体:阀体采用精密铸造,精确的几何尺寸使得阀体内部无需任何精加工即可保证阀门的密封性。

低温闸阀具有以下优点:

1、流体阻力小,密封面受介质的忡刷和侵蚀小。

2、开闭较省力。

3、介质流向不受限制,不扰流、不降低压力。

4、形体简单,结构长度短,制造工艺性好,适用范围广。

Light weight: the body is made of advanced ball black cast iron, which is about 20% ~ 30% lighter than the weight of traditional gate valve. Installation and maintenance are convenient.

Flat type brake block: traditional gate often wash the tube in the water after the external objects such as stone, wood, cement, iron filings, sundry sedimentation on the bottom of the valve such as the slots, easy to cause cannot close tightly and form slack phenomenon, at the bottom of the seal of the elastic base seat gate valves with water pipe with flat design, not easy to cause debris deposition, make the flow unimpeded.

The overall plastic bags: ram is made of high quality rubber, outsourcing, the whole Europe first-class rubber vulcanization technology make the gate to ensure accurate after vulcanization of geometry size, and rubber and ductile cast gate, then fall off not easily and elastic memory preferred.

Precision cast body: the valve body is made of precision casting and precise geometry allows the valve to be sealed without any precision.

Low temperature gate valve has the following advantages:

1. The fluid resistance is small and the sealing surface of the sealing surface is small with the brush and erosion of the medium.

2. It's easier to open and close.

3. The flow direction of the media is not restricted, not disturbing the flow, not reducing the pressure.

4. Simple form, short structure length, good manufacturing process and wide application scope.

产品特征 Spericfications

适用介质:水、气、油品、天然气和酸碱腐蚀性介质

适用温度:-196~425℃

驱动方式:手动、气动、电动等

公称压力:1.0~6.3MPa

公称通径:DN50~800mm

Applicable media: water, gas, oil, gas and acid and alkali corrosive medium

Applicable temperature: -196~425℃

Driver: manual, pneumatic, electric, etc

Nominal pressure: 1.0~6.3MPa

Nominal size: DN50~800mm

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12234 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T9113 HG20592 |

| 试验和检验 Test & inspection | GB/T 26480 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | |||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

反密封试验 Sealing test |

气密封试验 Air seal test |

| 1.0 | 1.5 | 1.1 | 1.1 | 0.6 |

| 1.6 | 2.4 | 1.76 | 1.76 | 0.6 |

| 2.5 | 3.75 | 2.75 | 2.75 | 0.6 |

| 4.0 | 6.0 | 4.4 | 4.4 | 0.6 |

| 6.3 | 9.45 | 6.93 | 6.93 | 0.6 |

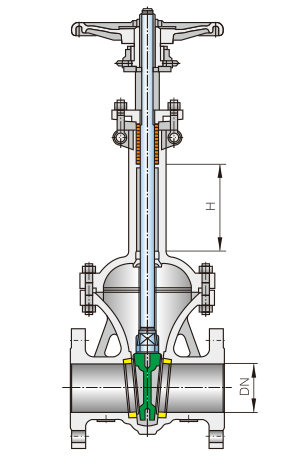

闸阀结构长度和外接尺寸 Main connection dimensions

| PN:1.0 1.6 2.5 4.0 6.3 | ||||

|

公称通径 DN |

温度 Temperature |

-46℃ | -101℃ | -196℃ |

| 50 | 110 | 130 | 170 | |

| 65 | 110 | 130 | 170 | |

| 80 | 120 | 150 | 190 | |

| 100 | 130 | 160 | 200 | |

| 125 | 130 | 160 | 200 | |

| 150 | 140 | 170 | 220 | |

| 200 | 140 | 170 | 220 | |

| 250 | 150 | 180 | 240 | |

| 300 | 150 | 180 | 240 | |

| 350 | 160 | 190 | 250 | |

| 400 | 160 | 190 | 250 | |

| 450 | 160 | 190 | 250 | |

| 500 | 170 | 200 | 260 | |

| 600 | 170 | 200 | 260 | |