Product Introduction

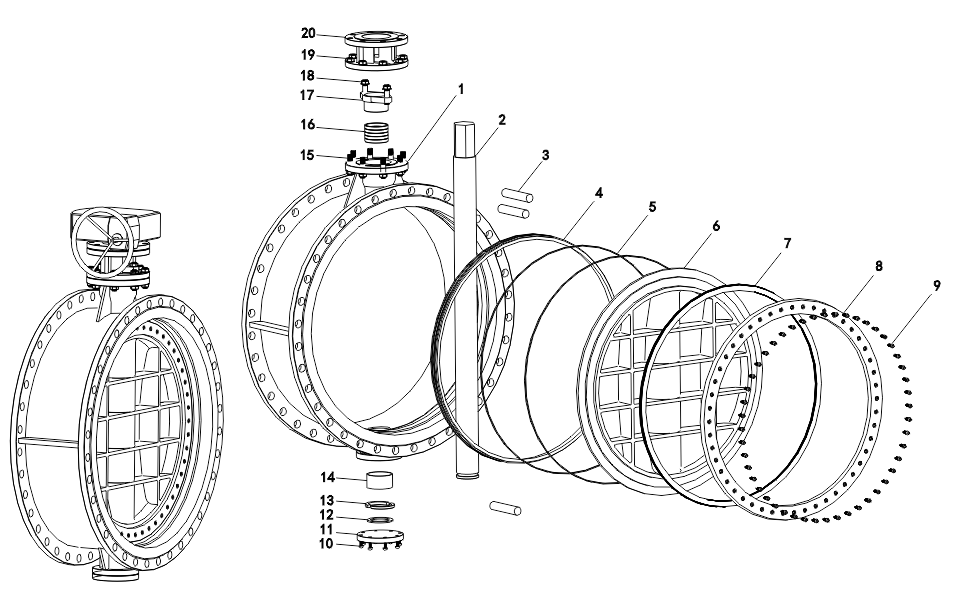

主要零件和材质 Main parts and materials

|

序号 NO |

零件名称 Accessor name |

材质 Material |

| GB系列 | ||

| 1 | 阀体 Body | WCB, LCB, CF8, CF3, CF8M, CF3M, WC6, WC9 |

| 2 | 阀杆 Stem | 20Cr13, 304, 304L, 316, 316L, 38CrMoAL, 25Cr2MoV |

| 3 | 圆锥轴 Taper pin | 20Cr13, 304, 304L, 316, 316L, 25Cr2MoV |

| 4 | 阀座 Seat | F304, F316, F316L |

| 5 | 蝶板 Disc | 丁腈橡胶 Rubber, 氟橡胶 Viton |

| 6 | O型圈 | WCB, LCB, CF8, CF3, CF8M, CF3M, WC6, WC9 |

| 7 | 密封圈 Sealing ring | 304/316+石墨, 304/316+PTFE, 304/316+橡胶 |

| 8 | 压板 Plate | Q235, F304, F316, F316L |

| 9 | 内六角螺钉 Nut | 35#, 304, 316, 316L |

| 10 | 内六角螺钉 Nut | 35#, 304, 316, 316L |

| 11 | 后盖 Bottom cover | Q235, F304, F316, F316L |

| 12 | 垫子 Gasket | PTFE 石墨 不锈钢 Stainless steel+石墨 Graphite |

| 13 | 对开环 Washer | 20Cr13, 304, 304L, 316, 316L, 25Cr2MoV |

| 14 | 轴套 Bush bearing | 自润滑复合轴套 304/316+PTFE |

| 15 | 螺柱 Bonnet bolt | 35#, 304, 316, 316L |

| 16 | 填料 Packing | 石墨 橡胶PTFE |

| 17 | 填料压盖 Gland | WCB, LCB, CF8, CF8M, WC6, WC9 |

| 18 | 螺柱 Bonnet bolt | 35#, 304, 316, 316L |

| 19 | 螺母 Nut | 45#, 304, 316, 316L |

| 20 | 支架 Yoke | WCB, CF8 |

产品结构特点 Construction features

1、 超长寿命设计

阀座、密封圈完全由金属材料制成,且做表面硬化处理,就算启闭频繁,阀门仍能保持高的密封性能,杜绝了多层次密封结构不耐冲刷等弊端,极大提高了阀门的使用寿命;

2、依靠扭矩密封

阀门至始至终都能保持优越的双向密封性能,阀门密封不依靠介质力,完全由驱动装置提供的扭矩实现密封,阀门在高、低压下均能可靠密封。密封性能检测结果符合API609、ISO5208等标准之规定;

3、阀座/密封圈可现场更换

可更换式阀座/密封圈设计,便于阀门现场维护保养;

4、填料密封的高性能

采用组合式填料密封系统,确保阀门最大泄漏率≤20ppm。可选用动载密封结构,使填料持久密封,延长填料免维护周期;

1. Long life design

Seat, sealing completely made of metal materials, and surface hardening treatment, even if the opening and closing is frequent, can still maintain a high sealing performance of the valve, put an end to the multi-layer sealing structure not scour resistance and other shortcomings, greatly improve the service life of the valve;

2. Rely on torque seal

Valve throughout can keep superior two-way sealing performance and valve sealing force does not rely on media, completely provided by the drive torque seal, valve can reliable sealing under high and low pressure. The sealing performance test results are in accordance with the standards of API 609 and ISO5208.

3. The seat/sealing ring can be replaced on site

Replaceable seat/sealing ring design to facilitate valve site maintenance;

4. High performance of packing seal

The combined packing sealing system is adopted to ensure the maximum leakage rate of valve is less than 20ppm. The movable seal structure can be used to keep the stuffing durable and prolong the packing period.

产品特征 Spericfications

适用介质:水、气、油品、天然气和酸碱腐蚀性介质

适用温度:-196~350℃

驱动方式:手动、气动、电动、液动等

公称压力:1.0~6.3MPa

公称通径:DN100~3600mm

Applicable media: water, gas, oil, gas and acid and alkali corrosive medium

Applicable temperature: -196~350℃

Driver: manual, pneumatic, electric, hydraulic, etc

Nominal pressure: 1.0~6.3MPa

Nominal size: DN100~3600mm

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12238 JB/T8527 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T9113 HG20592 |

| 试验和检验 Test & inspection | GB/T13927 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | |||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

反密封试验 Sealing test |

气密封试验 Air seal test |

| 0.6 | 0.9 | 0.66 | 0.66 | 0.6 |

| 1.0 | 1.5 | 1.1 | 1.1 | 0.6 |

| 1.6 | 2.4 | 1.76 | 1.76 | 0.6 |

| 2.5 | 3.75 | 2.75 | 2.75 | 0.6 |

| 4.0 | 6.0 | 4.4 | 4.4 | 0.6 |

| 6.3 | 9.45 | 6.93 | 6.93 | 0.6 |

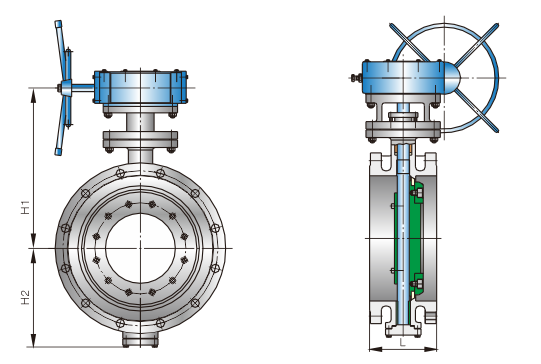

蝶阀结构长度和外接尺寸 Main connection dimensions

| PN:1.6~4.0 | |||||||

|

公称通径 DN |

L (mm) |

H1 (mm) |

H2 (mm) |

公称通径 DN |

L (mm) |

H1 (mm) |

H2 (mm) |

| 100 | 127 | 285 | 107 | 1000 | 410 | 1010 | 640 |

| 125 | 140 | 300 | 123 | 1200 | 470 | 1175 | 750 |

| 150 | 140 | 320 | 140 | 1400 | 530 | 1310 | 860 |

| 200 | 152 | 370 | 180 | 1600 | 600 | 1460 | 980 |

| 250 | 165 | 420 | 200 | 1800 | 670 | 1560 | 1090 |

| 300 | 178 | 500 | 250 | 2000 | 760 | 1670 | 1190 |

| 350 | 190 | 530 | 270 | 2200 | 590 | 1800 | 1440 |

| 400 | 216 | 570 | 300 | 2400 | 650 | 1930 | 1550 |

| 450 | 222 | 600 | 320 | 2600 | 700 | 2280 | 1660 |

| 500 | 229 | 680 | 360 | 2800 | 760 | 2460 | 1780 |

| 600 | 267 | 750 | 420 | 3000 | 810 | 2600 | 1940 |

| 700 | 292 | 810 | 480 | 3200 | 880 | 2760 | 2080 |

| 800 | 318 | 905 | 540 | 3400 | 950 | 2880 | 2200 |

| 900 | 330 | 960 | 590 | 3600 | 950 | 3020 | 2340 |