Product Introduction

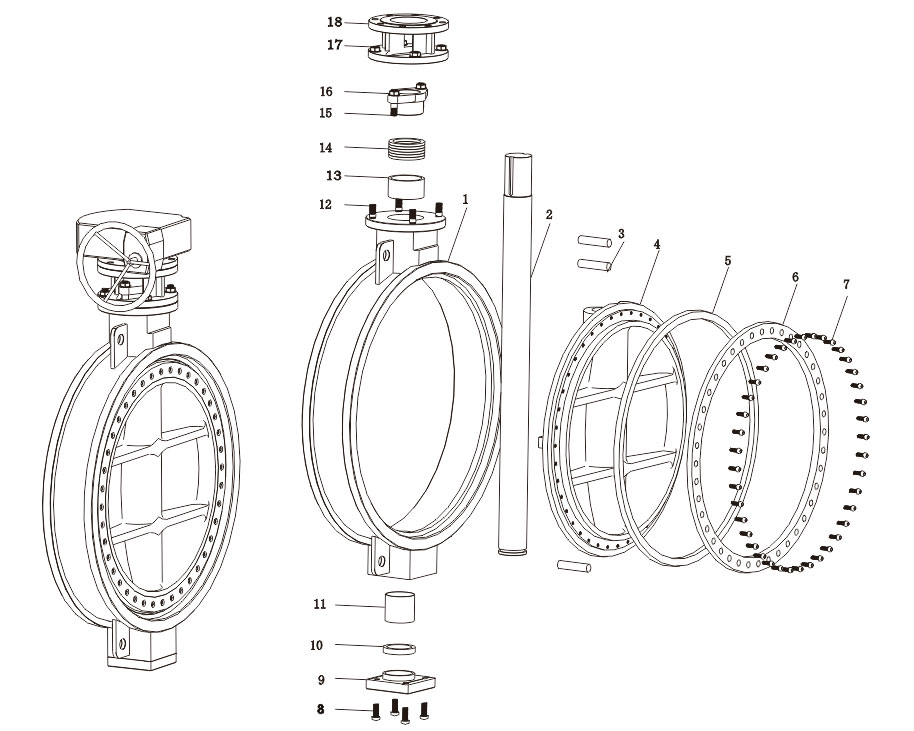

主要零件和材质 Main parts and materials

|

序号 NO |

零件名称 Accessor name |

材质 Material |

| GB系列 | ||

| 1 | 阀体 Body | WCB, LCB, CF8, CF3, CF8M, CF3M, WC6, WC9 |

| 2 | 阀杆 Stem | 20Cr13, 304, 304L, 316, 316L, 38CrMoAL, 25Cr2MoV |

| 3 | 圆锥轴 Taper pin | 20Cr13, 304, 304L, 316, 316L, 25Cr2MoV |

| 4 | 蝶板 Disc | WCB, LCB, CF8, CF3, CF8M, CF3M, WC6, WC9 |

| 5 | 密封圈 Sealing ring | 304/316+石墨, 304/316+PTFE, 304/316+橡胶 |

| 6 | 压板 Plate | Q235, F304, F316, F316L |

| 7 | 内六角螺钉 Nut | 35#, 304, 316, 316L |

| 8 | 内六角螺钉 Nut | 35#, 304, 316, 316L |

| 9 | 后盖 Bottom cover | Q235, F304, F316, F316L |

| 10 | 对开环 Washer | 20Cr13, 304, 304L, 316, 316L, 25Cr2MoV |

| 11 | 轴套 Bush bearing | 自润滑复合轴套 304/316+PTFE |

| 12 | 螺柱 Bonnet bolt | 35#, 304, 316, 316L |

| 13 | 轴套 Bush bearing | 自润滑复合轴套 304/316+PTFE |

| 14 | 填料 Packing | 石墨 橡胶PTFE |

| 15 | 填料压盖 Gland | WCB, LCB, CF8, CF8M, WC6, WC9 |

| 16 | 螺柱 Bonnet bolt | 35#, 304, 316, 316L |

| 17 | 螺母 Nut | 45#, 304, 316, 316L |

| 18 | 支架 Yoke | WCB, CF8 |

产品结构特点 Construction features

1、蝶板密封圈为软硬层叠式金属片,具有金属硬密封和弹性密封的双重优点,无论在低温和高温情况下,均具有优良的密封性能。

2、采用三维偏心结构,阀座与蝶板几乎无磨擦,具有越关越紧的密封功能。

3、阀体密封面,采用堆焊不锈钢、钴基硬质合金,密封面耐磨损,使用寿命长。

4、结构独特,操作灵活、省力、方便、不受介质压力的高、低影响,密封性能可靠,使用寿命长。

1. The butterfly plate sealing ring is a soft and hard laminated metal sheet, which has the double advantages of hard sealing and elastic sealing. It has excellent sealing performance both in low temperature and high temperature.2. Using the three-dimensional eccentric structure, the seat and butterfly plate are almost friction-free, and have the sealing function with the closer and tighter.

3. Body airtight cover, use of stacking stainless steel, cobalt base hard alloy, sealing surface wear resistance, long service life.

4. The structure is unique, the operation is flexible, the labor-saving, convenient, is not subjected to the medium pressure high, the low impact, the sealing performance is reliable, the service life is long.

产品特征 Spericfications

适用介质:水、气、油品、天然气和酸碱腐蚀性介质

适用温度:-196~350℃

驱动方式:手动、气动、电动、液动等

公称压力:0.6~4.0MPa

公称通径:DN100~1200mm

Applicable media: water, gas, oil, gas and acid and alkali corrosive medium

Applicable temperature: -196~350℃

Driver: manual, pneumatic, electric, hydraulic, etc

Nominal pressure: 0.6~4.0MPa

Nominal size: DN100~1200mm

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12238 JB/T8527 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T9113 HG20592 |

| 试验和检验 Test & inspection | GB/T13927 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | |||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

反密封试验 Sealing test |

气密封试验 Air seal test |

| 0.6 | 0.9 | 0.66 | - | 0.6 |

| 1.0 | 1.5 | 1.1 | - | 0.6 |

| 1.6 | 2.4 | 1.76 | - | 0.6 |

| 2.5 | 3.75 | 2.75 | - | 0.6 |

| 4.0 | 6.0 | 4.4 | - | 0.6 |

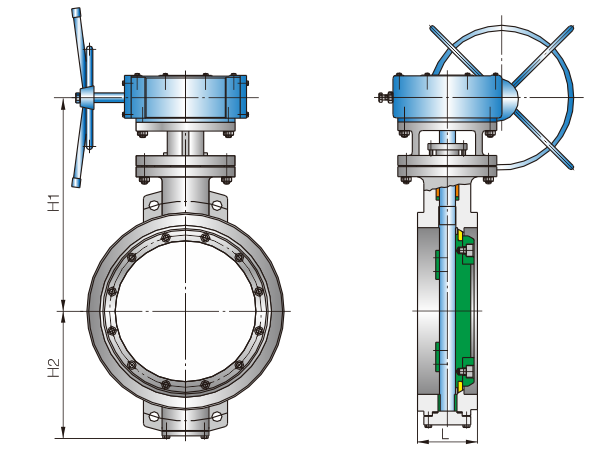

蝶阀结构长度和外接尺寸 Main connection dimensions

| PN:0.6~1.6 | |||||||

|

公称通径 DN |

L (mm) |

H1 (mm) |

H2 (mm) |

公称通径 DN |

L (mm) |

H1 (mm) |

H2 (mm) |

| 50 | 43 | 220 | 82 | 400 | 140 | 520 | 330 |

| 65 | 46 | 240 | 95 | 450 | 152 | 590 | 380 |

| 80 | 49 | 260 | 100 | 500 | 152 | 610 | 390 |

| 100 | 64 | 330 | 110 | 600 | 154 | 665 | 450 |

| 125 | 70 | 345 | 120 | 700 | 165 | 730 | 480 |

| 150 | 76 | 370 | 160 | 800 | 190 | 910 | 580 |

| 200 | 89 | 410 | 215 | 900 | 203 | 930 | 625 |

| 250 | 114 | 430 | 260 | 1000 | 216 | 1000 | 660 |

| 300 | 114 | 500 | 300 | 1200 | 254 | 1100 | 780 |

| 350 | 127 | 510 | 320 |

|

|

|

|