Product Introduction

产品结构特点 Construction features

1、产品设计制造按E101和JB/T 3595标准的规定,结构合理,性能优良,造型美观。

2、阀门中腔采用压力自紧式密封结构,介质压力越高,密封性能越好。

3、支管两端为焊接结构,适应不同的接管要求。

4、阀瓣、阀座密封面采用司太立(stellite)钴基硬质合金堆焊而成,耐磨、耐高温、耐腐蚀、抗擦伤性能好、使用寿命长。

5、高温耐压部件采用优质耐热合金钢制造,安全可靠,性能稳定,使用寿命长。

1. Product design and manufacturing shall be based on E101 and JB/T 3595 standard, with reasonable structure, excellent performance and beautiful appearance.

2. Pressure self-tightening seal structure is adopted in the valve middle cavity.The higher the medium pressure, the better the sealing performance.

3. The two ends of the branch are welded to meet different takeover requirements.

4. Disc, seat cover, and stellite (stellite) cobalt base alloy, which is used for hard wear, high temperature resistance, corrosion resistance, good abrasion resistance and long service life.

5. High temperature withstand pressure parts are made of high quality heat-resistant alloy steel, safe and reliable, stable performance and long service life.

产品特征 Spericfications

适用介质:水、气、油品、天然气和酸碱腐蚀性介质

适用温度:-196~540℃

驱动方式:手动、气动、电动等

公称压力:1.6~10.0MPa

公称通径:DN50~300mm

Applicable media: water, gas, oil, gas and acid and alkali corrosive medium

Applicable temperature: -196~540℃

Driver: manual, pneumatic, electric, etc

Nominal pressure: 1.6~10.0MPa

Nominal size: DN50~300mm

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12235 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T9113 HG20592 |

| 试验和检验 Test & inspection | GB/T 26480 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | |||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

反密封试验 Sealing test |

气密封试验 Air seal test |

| 1.0 | 1.5 | 1.1 | 1.1 | 0.6 |

| 1.6 | 2.4 | 1.76 | 1.76 | 0.6 |

| 2.5 | 3.75 | 2.75 | 2.75 | 0.6 |

| 4.0 | 6.0 | 4.4 | 4.4 | 0.6 |

| 6.3 | 9.45 | 6.93 | 6.93 | 0.6 |

| 10.0 | 15.0 | 11.0 | 11.0 | 0.6 |

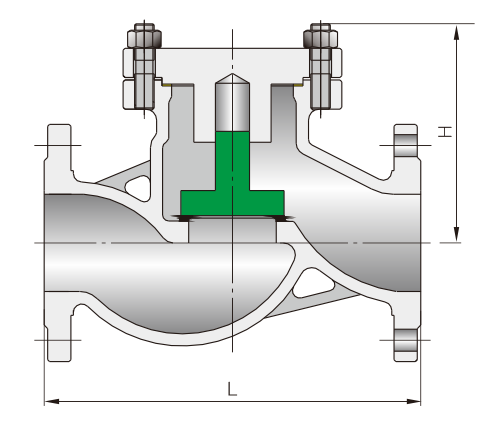

止回阀结构长度和外接尺寸 Main connection dimensions

| PN:1.6~4.0 | PN: 6.3~10.0 | |||

|

公称通径 DN |

L (mm) |

H (mm) |

L (mm) |

H (mm) |

| 50 | 230 | 140 | 300 | 190 |

| 65 | 290 | 150 | 340 | 205 |

| 80 | 310 | 170 | 380 | 230 |

| 100 | 350 | 185 | 430 | 280 |

| 125 | 400 | 195 | 500 | 300 |

| 150 | 480 | 225 | 550 | 350 |

| 200 | 600 | 250 | 650 | 400 |

| 250 | 650 | 270 |

|

|

| 300 | 750 | 300 |

|

|