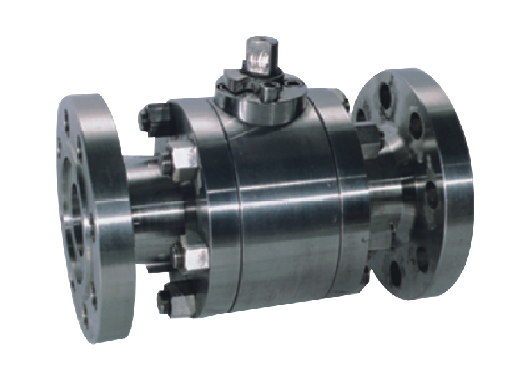

Product Introduction

产品结构特点 Construction features

1、先进的阀座:凭多方面经验而设计的阀座,确保阀门密封,摩擦系数低,操作力矩小。多种阀座材料,适应范围广。

2、开关无误的手柄:采用扁头阀杆,与手柄的连接不会错位,从而保证手柄指示的开关状态与阀门一致。

3、锁紧装置:为防止阀门开关误操作,在阀门全开、全关位置有锁定孔,确保阀门处于正确的位置。

4、阀杆防飞结构:阀杆为下装式,防止受压飞出,同时可在火灾后,与阀体形成金属接触,确保阀杆密封。

5、防静电性能:在球性、阀杆、阀体之间设置弹簧,能将开关过程产生的静电导出。

6、耐火结构:各个部位(球与阀体、中法兰、阀杆与阀体)设计成金属接触,满足

耐火要求,符合API 6FA,API 607的规定。

1. Advanced seat: seat designed with multiple experience to ensure valve seal, low friction coefficient and small operating torque. Multiple seat materials are widely used.

2. Unerror-free handle: use the flat head stem, and the connection of the handle will not be misaligned, thus ensuring that the switch state of the handle indicates the same as the valve.

3. Locking device: in order to prevent the valve switch from misoperation, the valve is fully open and the whole position has a locking hole to ensure that the valve is in the correct position.

4. Stem anti-flying structure: the stem is mounted to prevent the pressure from flying out, and the metal contact with the valve body can be formed after the fire to ensure the stem seal.

5. Anti-static performance: set up springs between ball, stem and valve body, and can export static electricity generated by switch process.

6. Refractory structure: various parts (ball and valve body, middle flange, stem and valve body) are designed to meet the fire resistance and meet the requirements of API 6FA and API 607.

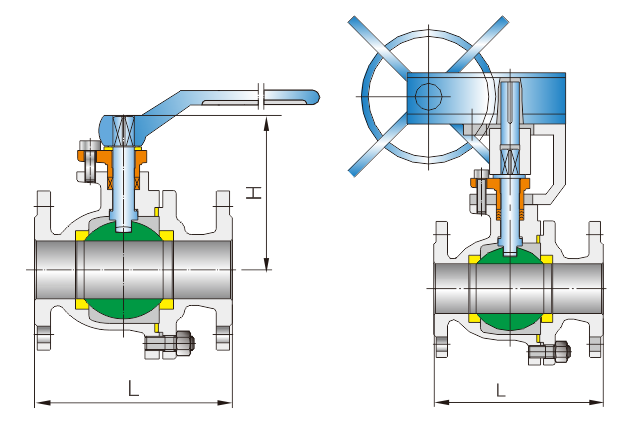

产品特征 Spericfications

适用介质:水、气、油品、天然气和酸碱腐蚀性介质

适用温度:-196~350℃

驱动方式:手动、气动、电动等

公称压力:1.0~6.3MPa

公称通径:DN15~250mm

Applicable media: water, gas, oil, gas and acid and alkali corrosive medium

Applicable temperature: -196~350℃

Driver: manual, pneumatic, electric, etc

Nominal pressure: 1.0~6.3MPa

Nominal size: DN15~250mm

主要零件和材质 Main parts and materials

|

序号 NO |

零件名称 Accessor name |

材质 Material |

| GB系列 | ||

| 1 | 阀体 Body | WCB, CF8, CF3, CF8M, CF3M |

| 2 | 阀座 Seat | (F304, F316, F316L, A105)+STL |

| 3 | 球体 Ball | (F304, F316, F316L, A105)+STL |

| 4 | 中垫 Gasket | 不锈钢+石墨 |

| 5 | 阀盖 Bonnet | WCB, CF8, CF3, CF8M, CF3M |

| 6 | 螺柱 Bonnet bolt | 35#, 304, 316, 316L |

| 7 | 螺母 Nut | 45#, 304, 316, 316L |

| 8 |

|

304, 316 |

| 9 | 阀杆 Stem | 20Cr13, 304, 304L, 316, 316L |

| 10 | 定位 Limited plate | 25+Cr 不锈钢 |

| 11 | 手柄 Lever | 玛钢WCB+Cr |

| 12 | 内六角螺钉 Nut | 35#, 304, 316 |

| 13 | 填料压盖 Gland | WCB, CF8, CF8M |

| 14 | 填料 Packing | PTFE 石墨 |

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12237 GB/T21385 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T9113 HG20592 |

| 试验和检验 Test & inspection | GB/T 26480 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | ||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

气密封试验 Air seal test |

| 1.0 | 1.5 | 1.1 | 0.6 |

| 1.6 | 2.4 | 1.76 | 0.6 |

| 2.5 | 3.75 | 2.75 | 0.6 |

| 4.0 | 6.0 | 4.4 | 0.6 |

| 6.3 | 9.45 | 6.93 | 0.6 |