Product Introduction

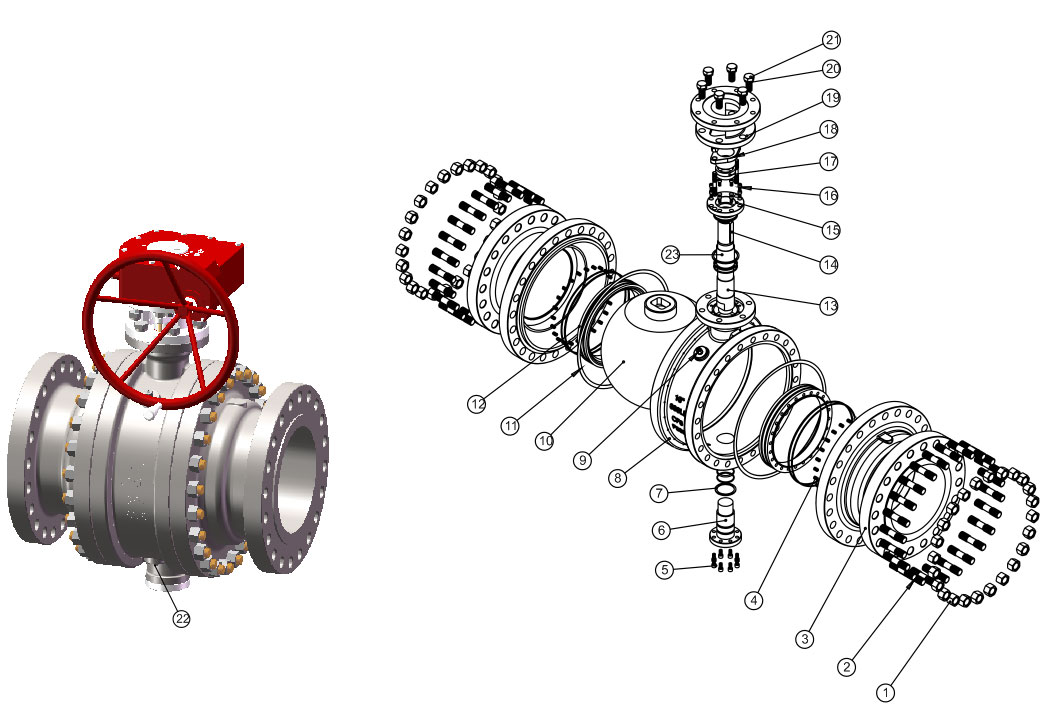

主要零件和材质 Main parts and materials

|

序号 NO |

零件名称 Accessor name |

材质 Material |

| GB系列 | ||

| 1 | 螺母 Nut | 45#, 304, 316, F316L |

| 2 | 螺柱 Bonnet bolt | 35#, 304, 316, F316L |

| 3 | 阀盖 Bonnet | WCB, LCB,CF8, CF3, CF8M, CF3M |

| 4 | 弹簧 Spring | 60Si2Mn, 304, 316, 17-7PH, Inconel750 |

| 5 | 内六角螺钉 Nut | 35#, 304, 316, F316L |

| 6 | 固定轴 Seat ring | 20Cr13, 304, 304L, 316, 316L |

| 7 | 垫子 Gasket | PTFE 不锈钢+石墨 |

| 8 | 阀体 body | WCB, LCB, CF8, CF3, CF8M, CF3M |

| 9 | 放空阀 Autocontol vtrol | 304 |

| 10 | 球体 Ball | 304, F304, F316, F316L, A105+ENP |

| 11 | 中垫 Gasket | PTFE 不锈钢+石墨 |

| 12 | 阀座 Seat | A105, F304, F316, F316L |

| 13 | 阀杆 Stem | 20Cr13, 304, 304L, 316, 316L |

| 14 | 普通平键 Key | 45# |

| 15 | 填料箱 Packing | A105, F304, F316 |

| 16 | 内六角螺钉 Nut | 35#, 304, 316, F316L |

| 17 | 填料 Packing | PTFE 石墨 |

| 18 | 填料压盖 Gland | WCB, CF8, CF8M |

| 19 | 支架 Yoke | WCB, CF8 |

| 20 | 弹性挡圈 Elostic retai ring | 60Si2Mn 17-7PH |

| 21 | 外六角螺柱 bonnet bolt | 35, 304, 316, 316L |

| 22 | 轴套 Bush bearing | 自润滑复合轴套 304/316+PTFE |

| 23 | 排污塞 Drain valve | A105, F304, F316 |

| 24 | 密封圈 Sealing ring | PTFE RPTFE PEEK PPL 尼龙 |

产品结构特点 Construction features

1、操作省力:介质压力在球体上产生作用力全部传递给上下轴承,球体不会相对位置移动,两端阀座密封受力均匀,操作力矩低。

2、采用弹簧预加载荷的可动金属阀座结构,能适用高温、高压以及各种介质管路。

3、根据客户要求,可以设计能适用于含颗粒、料浆等介质。

4、广泛适用于食品、医药、石油、化工、天然气、钢铁、环保、造纸等介质管路。

1. Operation saving force: the force of the medium pressure on the sphere is transmitted to the upper and lower bearings, the ball will not move relative position, the seating seal on both ends is uniform and the operating moment is low.

2. The movable metal seat structure with spring preloading can be used for high temperature, high pressure and various medium pipes.

3. According to customer requirements, it can be designed to be suitable for particles, slurry and other media.

4. It is widely used in food, medicine, petroleum, chemical, natural gas, steel, environmental protection, paper, etc.

产品特征 Spericfications

适用介质:水、气、油品、天然气和酸碱腐蚀性介质

适用温度:-196~150℃

驱动方式:手动、气动、电动、液动等

公称压力:1.0~16.0MPa

公称通径:DN50~1200mm

Applicable media: water, gas, oil, gas and acid and alkali corrosive medium

Applicable temperature: -196~150℃

Driver: manual, pneumatic, electric, hydraulic, etc

Nominal pressure: 1.0~16.0MPa

Nominal size: DN50~1200mm

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12237 GB/T21385 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T9113 HG20592 |

| 试验和检验 Test & inspection | GB/T 26480 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | |||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

反密封试验 Sealing test |

气密封试验 Air seal test |

| 1.0 | 1.5 | 1.1 | 1.1 | 0.6 |

| 1.6 | 2.4 | 1.76 | 1.76 | 0.6 |

| 2.5 | 3.75 | 2.75 | 2.75 | 0.6 |

| 4.0 | 6.0 | 4.4 | 4.4 | 0.6 |

| 6.3 | 9.45 | 6.93 | 6.93 | 0.6 |

| 10.0 | 15.0 | 11.0 | 11.0 | 0.6 |

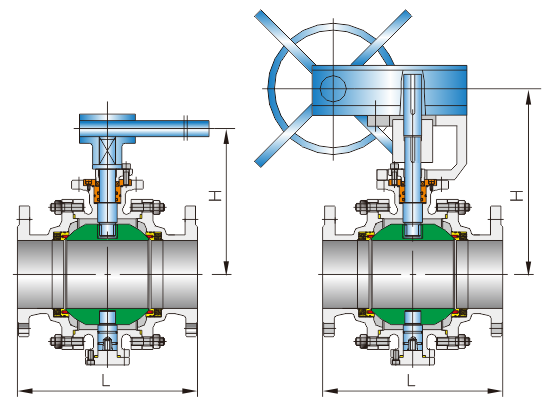

球阀结构长度和外接尺寸 Main connection dimensions

| PN:1.0~1.6 | PN:2.5~4.0 | PN:6.3 | PN:10.0 | |||||

|

公称通径 DN |

L (mm) |

H (mm) |

L (mm) |

H (mm) |

L (mm) |

H (mm) |

L (mm) |

H (mm) |

| 50 | 203 | 275 | 216 | 275 | 292 | 320 | 292 | 360 |

| 65 | 222 | 300 | 241 | 300 | 330 | 370 | 330 | 380 |

| 80 | 241 | 390 | 283 | 390 | 356 | 420 | 356 | 450 |

| 100 | 305 | 415 | 305 | 415 | 406 | 500 | 432 | 480 |

| 125 | 356 | 450 | 381 | 450 | 508 | 530 | 508 | 645 |

| 150 | 394 | 470 | 403 | 470 | 495 | 485 | 559 | 676 |

| 200 | 457 | 520 | 502 | 520 | 597 | 580 | 660 | 665 |

| 250 | 533 | 610 | 568 | 610 | 673 | 665 | 787 | 735 |

| 300 | 610 | 650 | 648 | 650 | 762 | 760 | 838 | 790 |

| 350 | 686 | 740 | 762 | 740 | 826 | 820 | 889 | 1020 |

| 400 | 762 | 795 | 838 | 795 | 902 | 870 | 991 | 1080 |

| 450 | 864 | 860 | 914 | 860 | 978 | 930 |

|

|

| 500 | 914 | 945 | 991 | 945 | 1054 | 995 |

|

|

| 600 | 1067 | 1040 | 1143 | 1040 | 1232 | 1100 |

|

|

| 700 | 1245 | 1150 | 1346 | 1150 | 1397 | 1180 |

|

|

| 800 | 1372 | 1280 | 1524 | 1305 | 1651 | 1345 |

|

|

| 900 | 1524 | 1430 | 1727 | 1505 | 1880 | 1550 |

|

|

| 1000 | 1753 | 1580 | 1880 | 1615 | 1981 | 1675 |

|

|

| 1200 | 2032 | 1810 | 2184 | 1925 | 2311 | 1945 |

|

|