Product Introduction

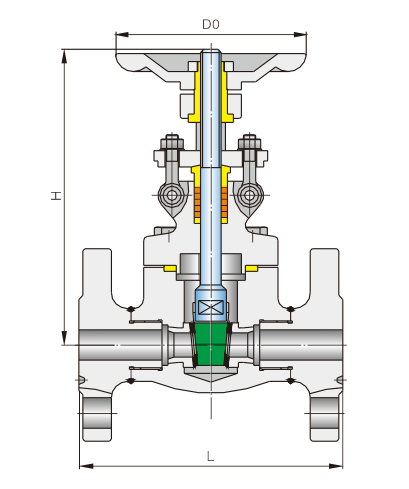

产品结构特点 Construction features

锻钢法兰端闸阀有三种阀盖设计形式。第一种是螺栓式阀盖,按这种设计的阀门,其阀体与阀盖用螺栓螺母连接,缠绕式垫片(316夹柔性石墨制造)。客户有特殊要求时也可采用金属环连接。

There are three types of bonnet design for forged flange end valves. The first type is bolted bonnet, which is designed to connect the valve body to the bonnet with bolt nuts and coil gasket (316 clip flexible graphite). Metal ring connections may also be used when customers have special requests.

产品特征 Spericfications

适用介质:水、气、油品、天然气和酸碱腐蚀性介质

适用温度:-196~425℃

驱动方式:手动、气动、电动等

公称压力:1.6~16.0MPa

公称通径:DN15~50mm

Applicable media: water, gas, oil, gas and acid and alkali corrosive medium

Applicable temperature: -196~425℃

Driver: manual, pneumatic, electric, etc

Nominal pressure: 1.6~16.0MPa

Nominal size: DN15~50mm

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12234 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T9113 HG20592 |

| 试验和检验 Test & inspection | GB/T26480 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | |||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

反密封试验 Sealing test |

气密封试验 Air seal test |

| 1.6 | 2.4 | 1.76 | 1.76 | 0.6 |

| 2.5 | 3.75 | 2.75 | 2.75 | 0.6 |

| 4.0 | 6.0 | 4.4 | 4.4 | 0.6 |

| 6.3 | 9.45 | 6.93 | 6.93 | 0.6 |

| 10.0 | 15.0 | 11.0 | 11.0 | 0.6 |

| 16.0 | 24.0 | 17.6 | 17.6 | 0.6 |

| 26.0 | 39.0 | 28.5 | 28.5 | 0.6 |

闸阀结构长度和外接尺寸 Main connection dimensions

| PN:1.6~4.0 | PN:6.4~10.0 | |||||

|

公称通径 DN |

L (mm) |

H (mm) |

D0 (mm) |

L (mm) |

H (mm) |

D0 (mm) |

| 15 | 130 | 180 | 100 | 170 | 180 | 100 |

| 20 | 150 | 185 | 100 | 190 | 185 | 100 |

| 25 | 160 | 215 | 125 | 210 | 215 | 125 |

| 32 | 180 | 225 | 160 | 230 | 225 | 160 |

| 40 | 200 | 245 | 160 | 240 | 245 | 160 |

| 50 | 250 | 285 | 180 | 250 | 285 | 180 |

| PN:16.0 | PN:26.0 | |||||

|

公称通径 DN |

L (mm) |

H (mm) |

D0 (mm) |

L (mm) |

H (mm) |

D0 (mm) |

| 15 | 170 | 195 | 125 | 216 | 195 | 125 |

| 20 | 190 | 195 | 125 | 229 | 195 | 125 |

| 25 | 210 | 220 | 160 | 254 | 220 | 160 |

| 32 | 230 | 245 | 160 | 279 | 245 | 160 |

| 40 | 260 | 280 | 180 | 305 | 280 | 180 |

| 50 | 300 | 305 | 200 | 368 | 305 | 200 |