Product Introduction

产品结构特点 Construction features

伸缩阀适用于温度≤425℃,公称压力≤1.6MPa的食品、医药、化工、石油、电力、轻纺、造纸等给排水、气体管道上作调节流量和截流介质的作用,具有补偿管道热胀冷缩的功能。

其主要特点为:

1、设计新颖、合理,结构独特,重量轻,操作方便,启闭迅速;

2、伸缩蝶阀除了能作调节和截流作用,补偿管道温差所产生的热胀冷缩功能外,还能为安装更换、维修阀门提供方便;

3、密封部位可调节更换,密封性能可靠等特点。

Expansion valve is suitable for the temperature of 425℃ or less and nominal pressure of 1.6 MPa or less food, medicine, chemical, petroleum, electric power, textile,paper and other water supply and drainage, for adjusting flux on the gas pipeline and intercepting the role of the media, has the function of compensating pipe heat bilges cold shrink.

Its main features are:

1. The design is novel and reasonable, the structure is unique, the weight is light,

the operation is convenient, the opening and closing fast;

2. In addition to adjusting and intercepting the butterfly valve, it can also provide convenient installation and replacement and maintenance of valve.

3. The sealing parts can be adjusted and replaced, and the sealing performance is reliable.

产品特征 Spericfications

适用介质:食品、石油、化工、电力、造纸和

适用温度:-29~350℃

驱动方式:手动、气动、电动、液动等

公称压力:0.6~1.6MPa

公称通径:DN100~2000mm

Applicable media: Gas, dust and flue gas

Applicable temperature: -29~350℃

Driver: manual, pneumatic, electric, hydraulic, etc

Nominal pressure: 0.6~1.6MPa

Nominal size: DN100~2000mm

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12238 JB/T8527 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T9113 GB/T17241.6 |

| 试验和检验 Test & inspection | GB/T13927 |

主要零件和材质 Main parts and materials

|

序号 NO |

零件名称 Accessor name |

材质 Material |

| GB系列 | ||

| 1 | 阀体 Body | QT450-10 0.5Cr0.5Ni WCB CF8 |

| 2 | 蝶板 Disc | QT450-10 0.5Cr0.5Ni WCB CF8 |

| 3 | 密封圈 Sealing ring | EPDM NBR 304 |

| 4 | 阀杆 Stem | 20Cr13 304 316 |

| 5 | 伸缩管 | QT450-10 0.5Cr0.5Ni WCB CF8 |

| 6 | 填料 Packing | 石墨 橡胶 |

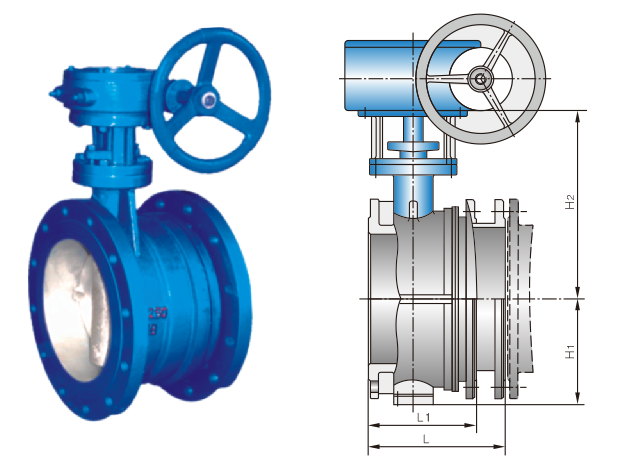

蝶阀结构长度和外接尺寸 Main connection dimensions

| PN:0.6~1.6 | |||||||||

|

公称通径 DN |

L (mm) |

L1 (mm) |

H1 (mm) |

H2 (mm) |

公称通径 DN |

L (mm) |

L1 (mm) |

H1 (mm) |

H2 (mm) |

| 100 | 216 | 174 | 110 | 170 | 600 | 420 | 370 | 390 | 490 |

| 125 | 232 | 186 | 123 | 182 | 700 | 446 | 396 | 450 | 560 |

| 150 | 239 | 194 | 140 | 210 | 800 | 476 | 426 | 515 | 625 |

| 200 | 264 | 214 | 170 | 238 | 900 | 506 | 456 | 560 | 685 |

| 250 | 296 | 235 | 195 | 270 | 1000 | 516 | 466 | 610 | 750 |

| 300 | 300 | 250 | 222 | 300 | 1200 | 560 | 510 | 725 | 880 |

| 350 | 320 | 270 | 252 | 330 | 1400 | 590 | 540 | 840 | 987 |

| 400 | 332 | 282 | 285 | 368 | 1600 | 630 | 585 | 960 | 1158 |

| 450 | 355 | 305 | 310 | 410 | 1800 | 680 | 630 | 1060 | 1260 |

| 500 | 365 | 315 | 335 | 440 | 2000 | 730 | 680 | 1165 | 1365 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | |||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

反密封试验 Sealing test |

气密封试验 Air seal test |

| 0.6 | 0.9 | 0.66 | - | 0.6 |

| 1.0 | 1.5 | 1.1 | - | 0.6 |

| 1.6 | 2.4 | 1.76 | - | 0.6 |