Product Introduction

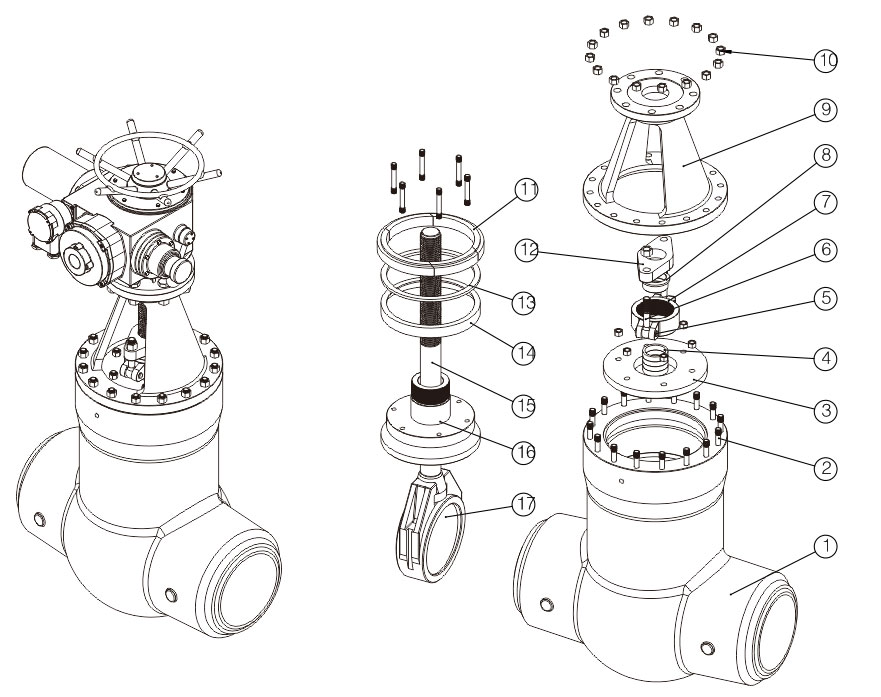

主要零件和材质 Main parts and materials

|

序号 NO |

零件名称 Accessor name |

材质 Material |

| GB系列 | ||

| 1 | 阀体 Body | WCB, WC6, WC9, 20CrMoV, 15Cr1MoV |

| 2 | 螺柱 Bonnet bolt | 35#, 45# |

| 3 | 阀盖 Bonnet | WCB, WC6, WC9, 20CrMoV, 15Cr1MoV |

| 4 | 填料 Packing | 石墨 |

| 5 | 圆柱销 Tin | 20Cr13 |

| 6 | 支架螺母 Nut | 45# |

| 7 | 千斤座 Topping bracket | WCB, WC6 |

| 8 | 填料压套 Gland | WCB, WC6, WC9 |

| 9 | 支架 Yoke | WCB |

| 10 | 六角螺母 Nut | 45# |

| 11 | 四开环 Pendant colet | A105, 20CrMoV, 15Cr1MoV |

| 12 | 填料压盖 Gland | WCB, WC6 |

| 13 | 密封垫 Gaskes | F304, 20CrMoV, 15Cr1MoV |

| 14 | 密封环 Seal ring | 石墨 PTFE, 316L |

| 15 | 阀杆 Stem | 20Cr13, 38CrMoAL, 25CrKMoV |

| 16 | 浮动座 Floating seat | 20Cr13, 38CrMoAL, 25CrKMoV |

| 17 | 闸板 Wedge | WCB, WC6, WC9 |

| 18 | 阀杆螺母 Stem nut | ZCuAl10Fe3 |

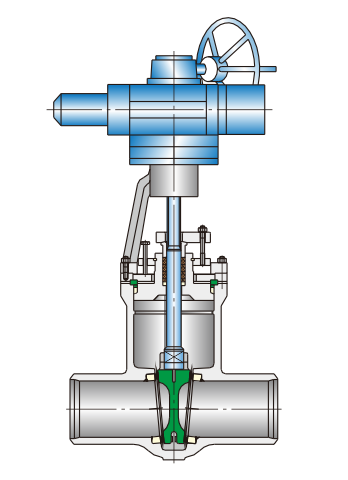

产品结构特点 Construction features

1、符合GB标准的要求,结构合理、密封可靠、性能良好、造型美观。

2、材料品种齐全、填料、垫片可根据用户不同要求合理选配,能适用于各种压力、 温度及介质工况,高温阀门耐压部件选用优质耐热合金钢制造,密封面采用司太立(stellite)钴基硬质合金,安全可靠,性能稳定,使用寿命长。

3、阀体阀盖结构设计合理,壁厚经严格控制及检测符合国家标准GB12234及美国标准ANSI B16.34要求,强度高、刚性好、流阻小。

4、采用楔式弹性闸板结构,经整体精铸制成,造型精美,密封性能好。

5、阀杆采用耐热合金钢,经锻粗和调质及表面氮化处理,有良好的综合力学性能和抗腐蚀性,抗擦伤性。

6、闸阀全部采用倒密封结构,可在不停机工况下进行维修或增改填料。

7、阀杆螺母采用内函式结构,与支架连接部位设置滚珠轴承,转动力矩小、启闭轻松。

8、根据用户或工程要求合理选择连接形式,多种操作方式可满足不同的使用要求。

1. Accord with GB standard, reasonable structure, reliable sealing, good performance and beautiful appearance.

2. Variety complete, packing and gasket materials reasonable matching, can according to customer's request to apply to all kinds of pressure, temperature and medium conditions, high pressure valve selects high quality alloy steel manufacturing, sealing surface using department too vertical (stellite) cobalt-based hard alloy, safe and reliable, stable performance and long service life.

3. The valve bonnet structure is reasonable, the wall thickness is strictly controlled and the test conforms to the national standard GB12234 and the American standard ANSI B16.34, the strength is high, the rigidity is good, the flow resistance is small.

4. Using wedge-type elastic gate structure, it is made of whole cast, with fine design and good sealing performance.

5. The stem is made of heat-resistant alloy steel with good mechanical properties and corrosion resistance and abrasion resistance.

6. Gate valves shall be fully resealed, which may be repaired or modified in unstopped working conditions.

7. The stem nut adopts the internal function structure, the ball bearing is set up with the connecting part of the bracket, the torque is small and the lifting is easy.

8. According to the requirements of users or engineering, the connection form should be reasonably selected, and various operation modes can meet different usage requirements.

产品特征 Spericfications

适用介质:水、气、油品、天然气和酸碱腐蚀性介质

适用温度:-196~540℃

驱动方式:手动、气动、电动等

公称压力:20.0~32.0MPa

公称通径:DN50~300mm

Applicable media: water, gas, oil, gas and acid and alkali corrosive medium

Applicable temperature: -196~540℃

Driver: manual, pneumatic, electric, etc

Nominal pressure: 20.0~32.0MPa

Nominal size: DN50~300mm

技术规范 Technical specification

| 设计依据 Design reference | GB系列 GB series |

| 设计标准 Design standard | GB/T12236 NB/T47044 DL531 |

| 结构长度 Face to face | GB/T12221 |

| 连接法兰 End flange | GB/T12224 |

| 试验和检验 Test & inspection | GB/T 26480 |

试验压力 Test prssure

|

压力等级 Pressure grade |

试验压力 Test pressure | |||

|

公称压力 PN Nominal pressure |

壳体试验 Sheil test |

正密封试验 Sealing test |

反密封试验 Sealing test |

气密封试验 Air seal test |

| 20.0 P54 10V | 30.0 | 22.0 | 22.0 | 0.6 |

| 25.0 P54 14V | 37.5 | 27.5 | 27.5 | 0.6 |

| 32.0 P54 17V | 48.0 | 32.5 | 32.5 | 0.6 |

| P55 10V | 37.5 | 27.5 | 27.5 | 0.6 |

| P55 14V | 48.0 | 36.0 | 36.0 | 0.6 |

| P55 17V | 53.0 | 39.0 | 39.0 | 0.6 |

| P57 10V | 48.0 | 36.0 | 36.0 | 0.6 |

| P57 14V | 53.0 | 39.0 | 39.0 | 0.6 |

| P57 17V | 60.0 | 44.0 | 44.0 | 0.6 |

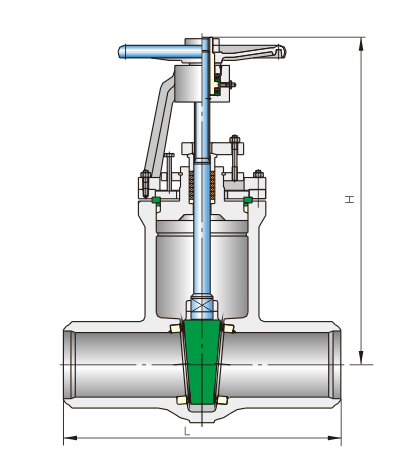

闸阀结构长度和外接尺寸 Main connection dimensions

| PN:20.0 P54 100V | PN:25.0 P54 140V | PN:32.0 P54 170V | ||||

|

公称通径 DN |

L (mm) |

H (mm) |

L (mm) |

H (mm) |

L (mm) |

H (mm) |

| 50 | 216 | 640 | 216 | 640 |

|

|

| 65 | 254 | 680 | 254 | 680 |

|

|

| 80 | 305 | 715 | 305 | 715 |

|

|

| 100 | 356 | 755 | 406 | 755 | 457 | 755 |

| 125 | 432 | 830 | 48/3 | 830 | 533 | 830 |

| 150 | 508 | 1050 | 559 | 1050 | 610 | 1050 |

| 175 | 650 | 1050 | 700 | 1050 | 750 | 1050 |

| 225 | 850 | 1050 | 850 | 1050 | 850 | 1050 |

| 250 | 864 | 1100 | 914 | 1100 | 914 | 1100 |

| 300 | 991 | 1200 |

|

|

|

|