Product Introduction

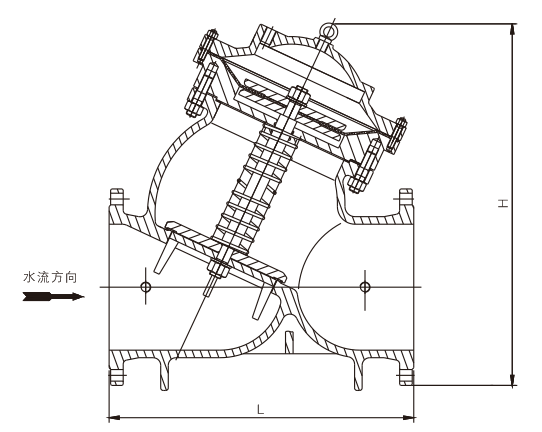

斜体式水力控制阀也是一种自动类阀门,它的动作原理、结构与隔膜式水力控制阀基本一致。它具有隔膜式同样的优点和功能,它的感应部件同样是膜片,主要不同之处是主阀体采用斜体式,这样使该类阀门比隔膜式和活塞式的流阻系数更小,流量更大。而且通过对膜片下腔的结构及阀瓣结构的改进,使该阀的调节性更好。

斜体式的膜片室的结构与前面介绍的膜片式水力控制阀不同。如上图所示,膜片室的下腔被设计成独立的空腔,它可以根据不同用途选择是否与主阀腔相通。这样不但可以实现上下膜片室单独控制,从而可使用外部的压力源驱动阀门的开关,而不受介质压力的限制,又能实现缓开缓闭等功能。

斜体式水力控制阀的上、下膜片室、膜片组件、阀杆、阀瓣等部件可整体拆下取出,这给维修带来了极大的方便。

斜体式水力控制阀的阀杆采用中段导向,避免了阀杆两端导向易出现不同心的弊端。

The italic hydraulic control valve is also an automatic type valve, which is basically consistent with the operating principle, structure and diaphragm type hydraulic control valve. It have the same advantages and functions of the diaphragm type,its sensing part is also a diaphragm, the main difference is the italic type is used in the main body, such making that the class than the diaphragm and piston valve flow resistance coefficient of smaller, more traffic. Moreover, the valve is better adjusted by improving the structure of the cavity and the valve structure.

The structure of italic diaphragm is different from the diaphragm type hydraulic control valve described earlier. As shown in the figure above, the lower cavity of the diaphragm chamber is designed as an independent cavity, which can be used to select whether or not it is connected to the main valve cavity. In this way,not only can the diaphragm chamber be controlled separately, but the external pressure source can be used to drive the valve's switch, without the restriction of media pressure, and can realize the function of easing and closing.

The upper and lower diaphragm chamber, diaphragm assembly, valve stem, disc and other parts can be removed and removed, which brings great convenience to the maintenance.

The valve stem of italic hydraulic control valve adopts the middle section guide,avoiding the disadvantages of different heart on both ends of the stem.

执行标准 Executive standard

法兰尺寸:GB/T 17241.6

试验检验:GB/T 13927

性能规范 Performance specification

| 公称通径 Nominal diameter DN | 50~1000 |

|

|

mm |

| 公称压力 Nominal pressure PN | 1.0 | 1.6 | 2.5 | Mpa |

| 壳体试验 Shell test | 1.5 | 2.4 | 3.75 | |

| 密封试验 Sealing test | 1.1 | 1.76 | 2.75 | |

| 气密封试验 Gas seal test | 0.6 | 0.6 | 0.6 | |

| 适用温度 Suitable temperature | ≤100 | ℃ | ||

| 适用介质 Applicable medium | 水Water | |||

注:1、PN=2.5MPa时阀体、阀盖材料为铸钢,法兰尺寸执行GB9113.1

2、主阀外的控制管路、导阀、管件等均为铜合金。

3、橡胶件也可选用三元乙丙或氟橡胶。

主要零件材料 Major part material

| 零件 Part | 材料 Material |

| 阀体、阀盖 Valve body, cover | 灰铸铁/球墨铸铁Gray cast iron/nodular cast iron |

| 阀杆 Valve stem | 不锈钢 Stainless steel |

| 膜片 Diaphragm | 增强丁腈橡胶 Enhanced butadiene rubber |

| 阀瓣密封圈 Disc seal | 橡胶 Rubber |

| 弹簧 Spring | 不锈钢 Stainless steel |

| 阀瓣、阀座 Disc, valve seat | 铜合金 Copper alloy |

| 表面涂装 Surface coating | 环氧树脂 Epoxy resin |